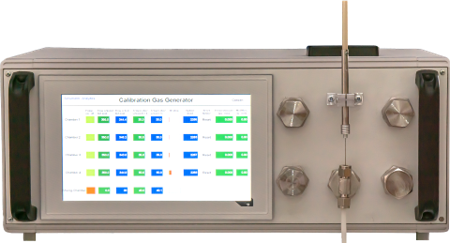

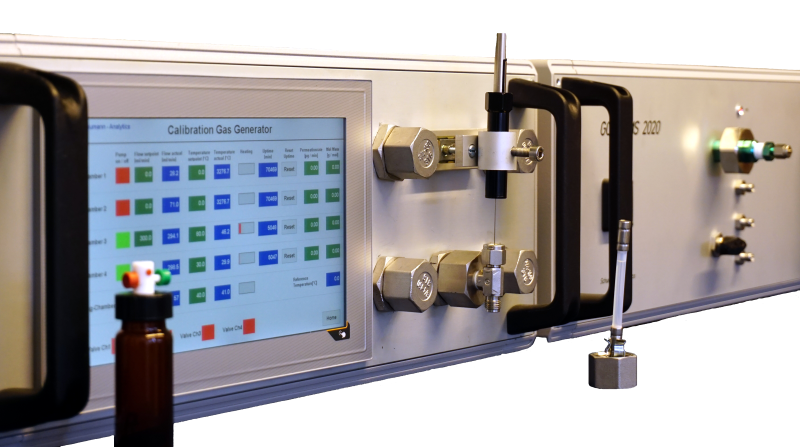

Calibration Gas Generator CGG 800

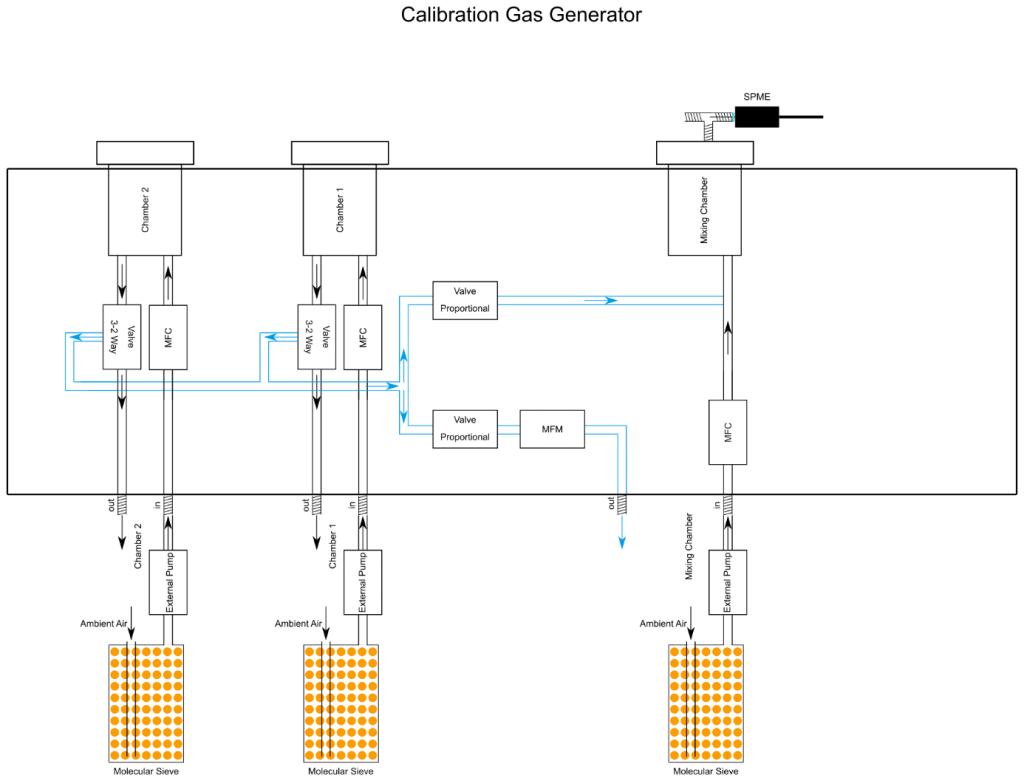

Our calibration gas generators are used to produce calibration standards in the lower ppb to % range. Based on the permeation method according to ASTM D 3609-96, this technology is a cost-effective alternative to the most commonly used test gases in steel cylinders. The gas generators are equipped with high-precision thermal gas flow controllers and can also generate complex gas mixtures over a long period of time due to the multi-chamber system. The permeation chambers are inert due to a special coating process, thus eliminating adsorption effects on the outer walls and ensuring high reproducibility. In addition, high-precision proportional valves ensure a precise splitting function. As a result, high dilution flow rates in lower concentration ranges can be avoided.

Operating principle

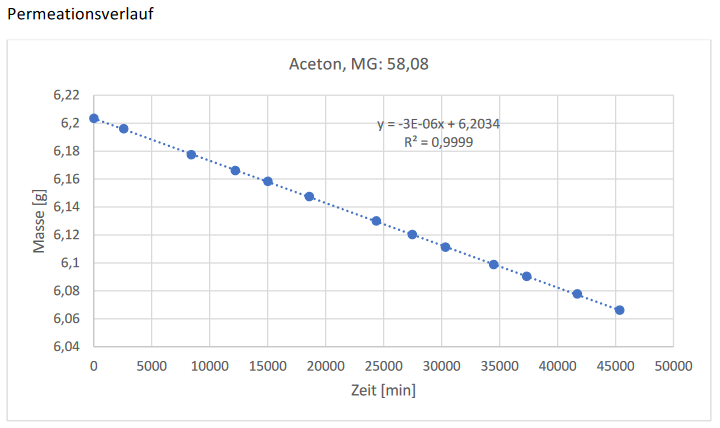

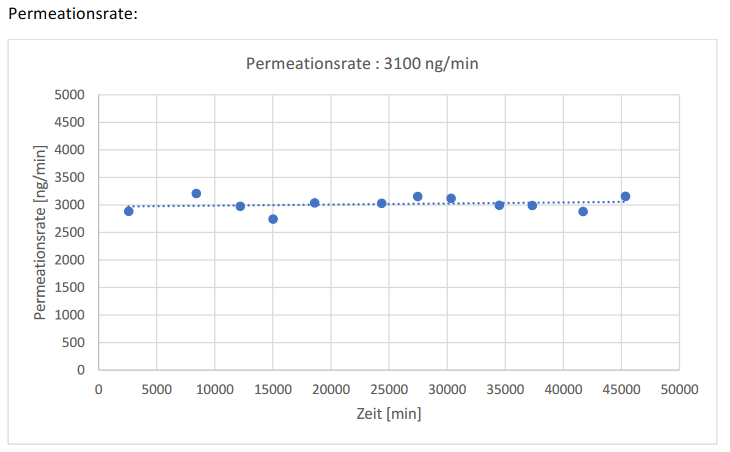

The basis of the dynamic, continuous process is the permeation of the substance of interest through a suitable membrane into a basic gas flow. The pure substance (liquid or solid) is contained in a permeation tube fitted with a membrane. This tube is completely surrounded by a pure base gas with a constant volume flow, which absorbs the molecules emerging from the membrane. The permeation rate depends on the substance itself, the type of membrane, the temperature and the concentration gradient on both sides of the membrane. This is determined either by weighing the permeation vessels, by comparative measurements with test gases of known concentration using analyser systems of the highest accuracy or by direct analysis. Provided that the permeation rate remains constant between the weighings, it is calculated from the quotient of the change in mass and the time difference.

Technical features

- Up to four stainless steel permeation chambers, coated with Siconert 2000® (Sulfinert®)®(Sulfinert®)

- One coated mixing chamber for direct gas sampling

- Additional receptacle for a SPME enrichment unit

- All parameters such as temperatures, gas flows, permeation rates and split ratios can be easily set via a 10.1" touch panel

- Integrated timer for calculating the permeation rates

- High-precision thermal mass flow controllers with an accuracy of < 1%

- All chambers are equipped with integrated diaphragm pumps, therefore an external gas supply is not necessary but possible

- Individual temperature and gas flow settings from room temperature up to 150°C respectively 10 ml/min up to 500 ml/min for each chamber